|

CMS Pixel Detector

Miscellaneous

|

|

Phase 1

Phase 2

|

|

Layer 1 Replacement

Layers 2-4

|

| Layer 1 Replacement Elog |

Not logged in |

|

|

|

|

Message ID: 5

Entry time: Wed Aug 7 11:49:07 2019

|

| Author: |

Matej Roguljic |

| Category: |

Module assembly |

| Subject: |

HDI glue irradiation tests |

|

|

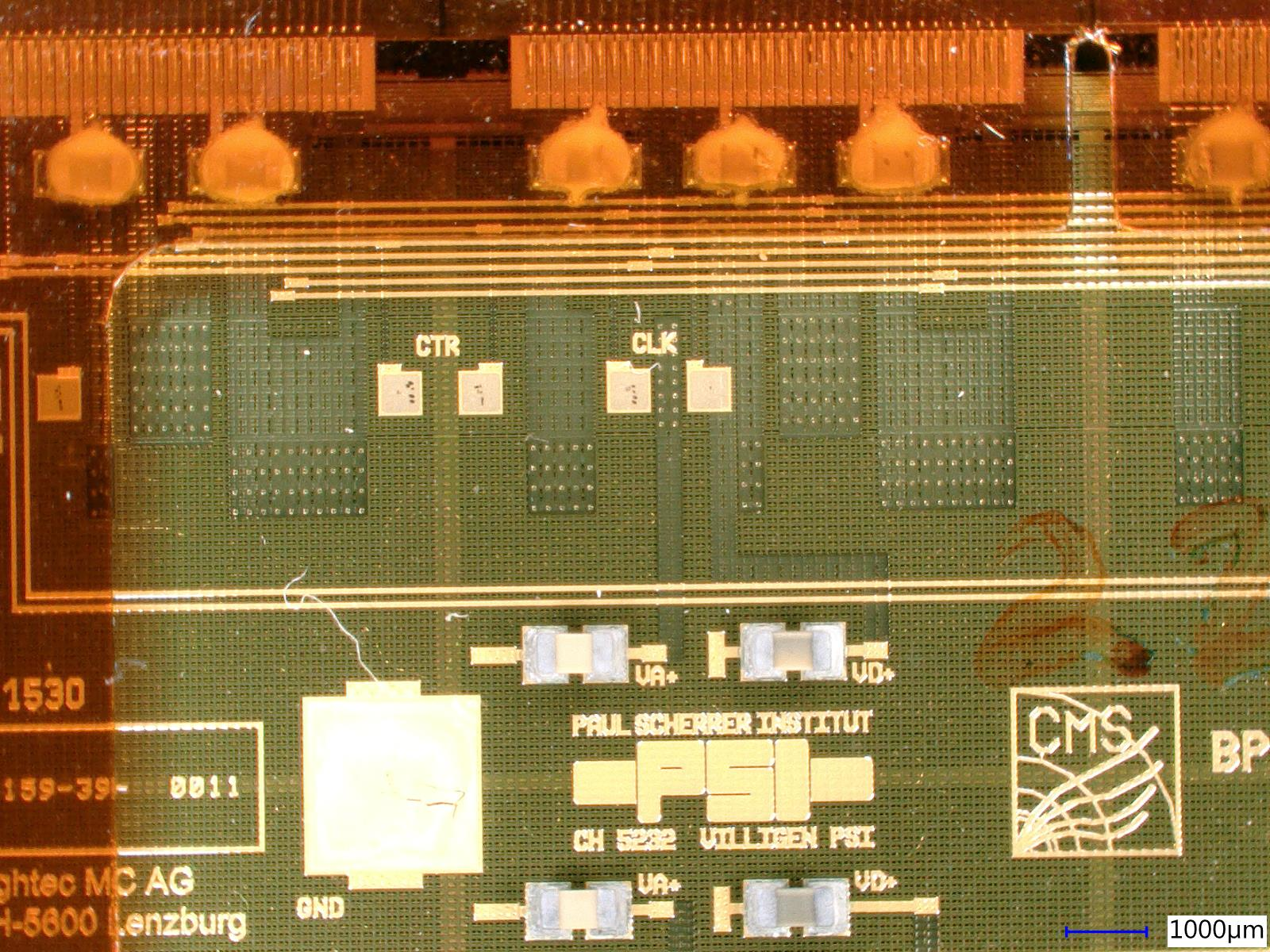

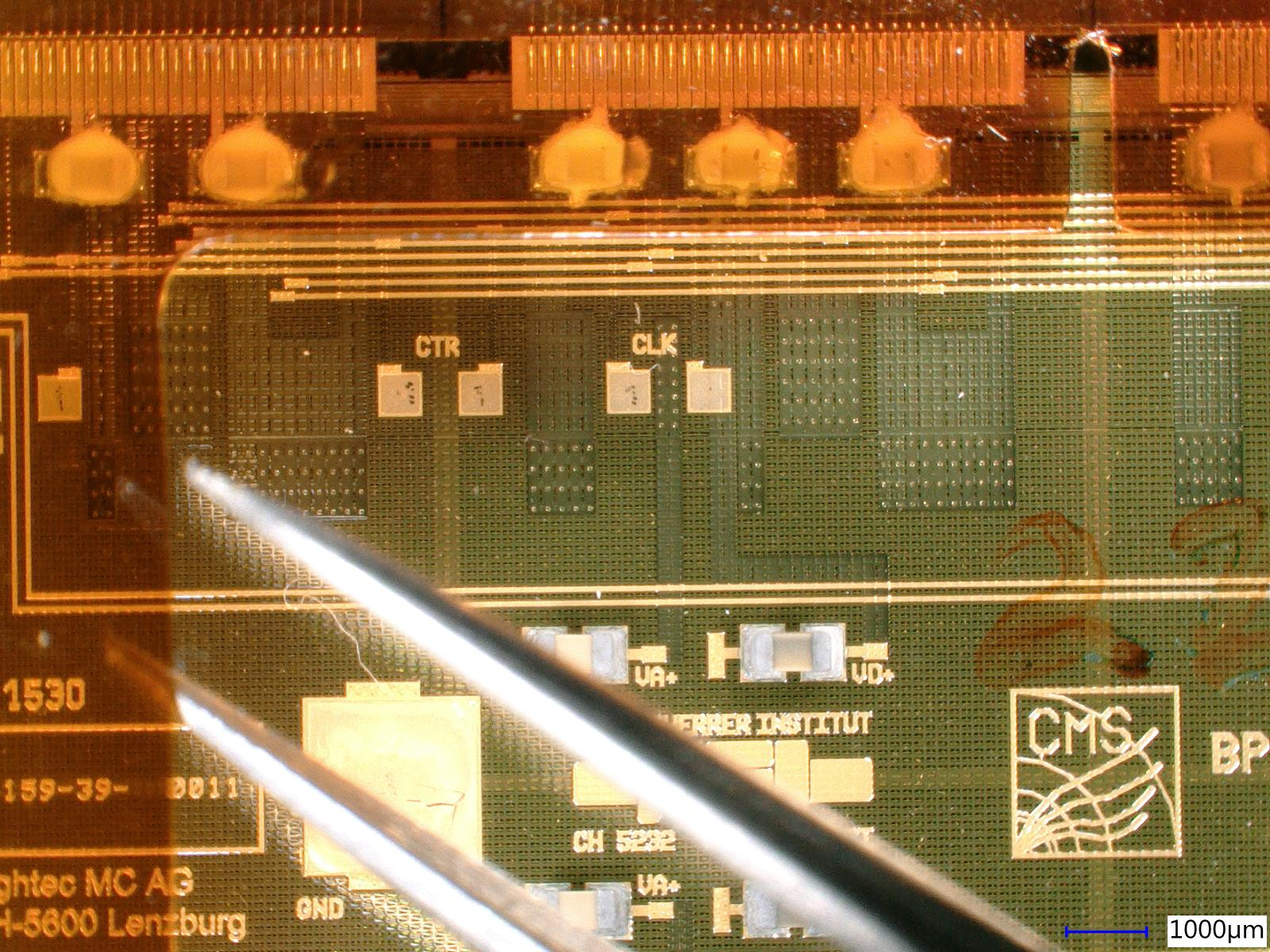

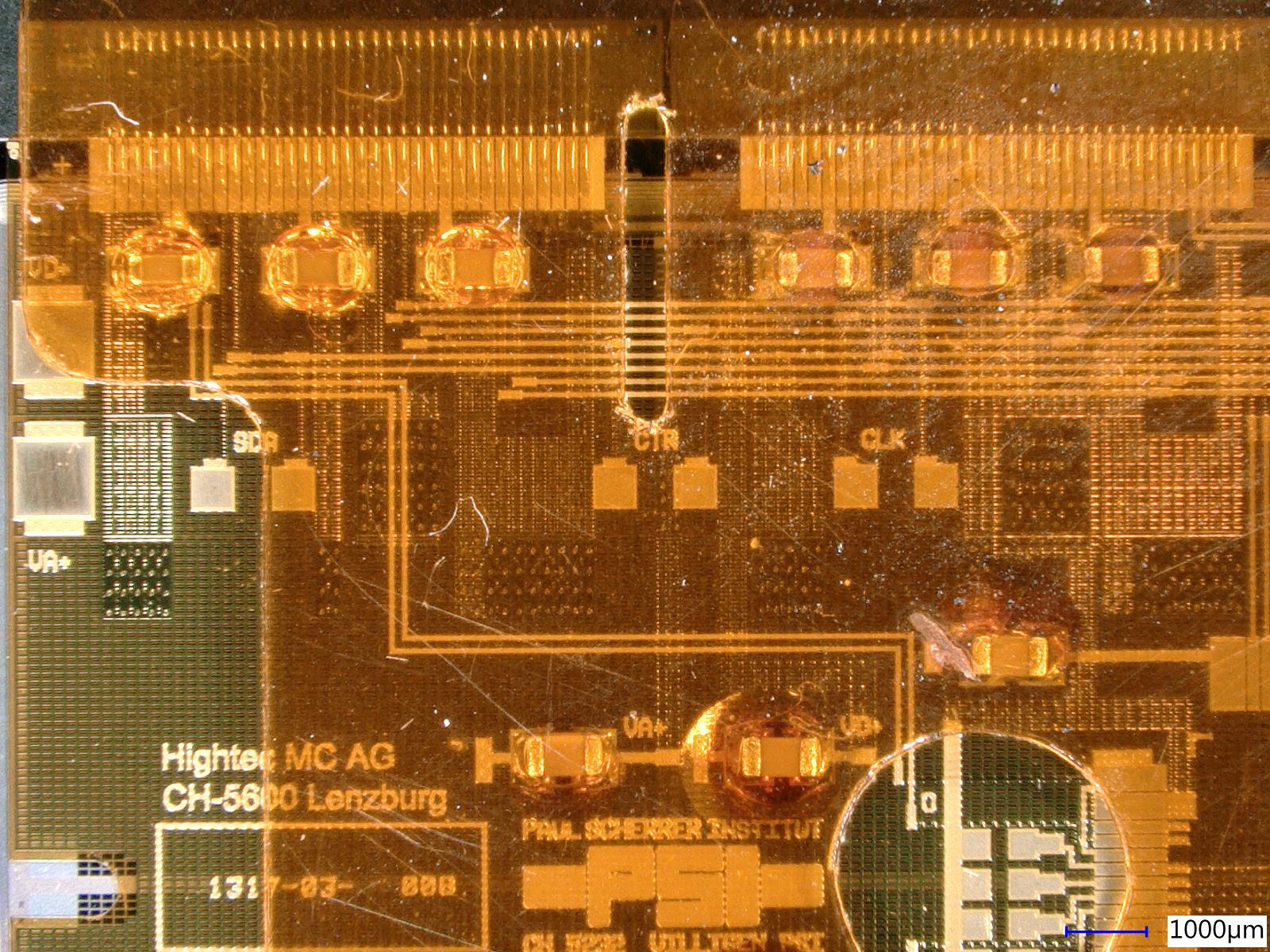

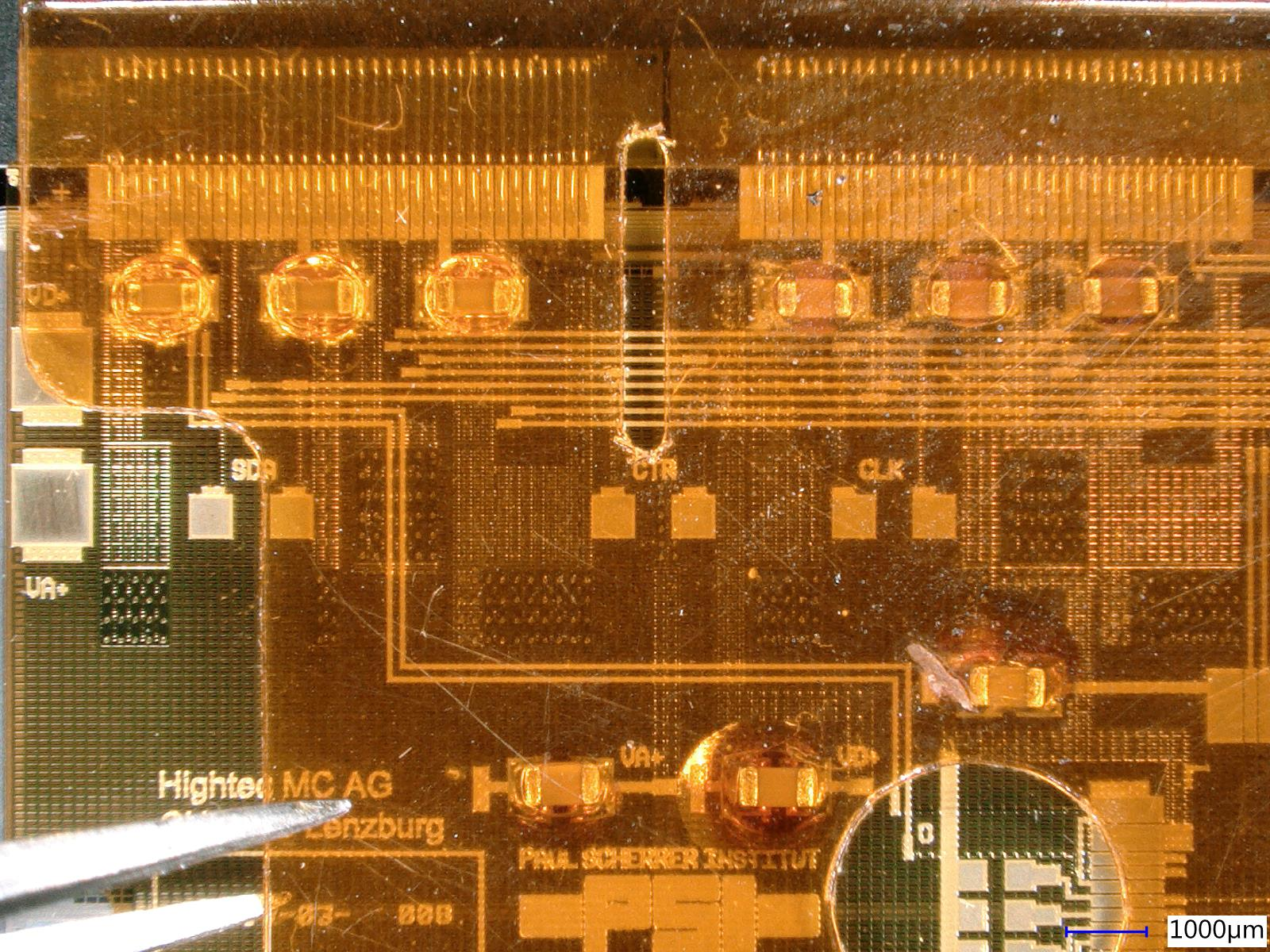

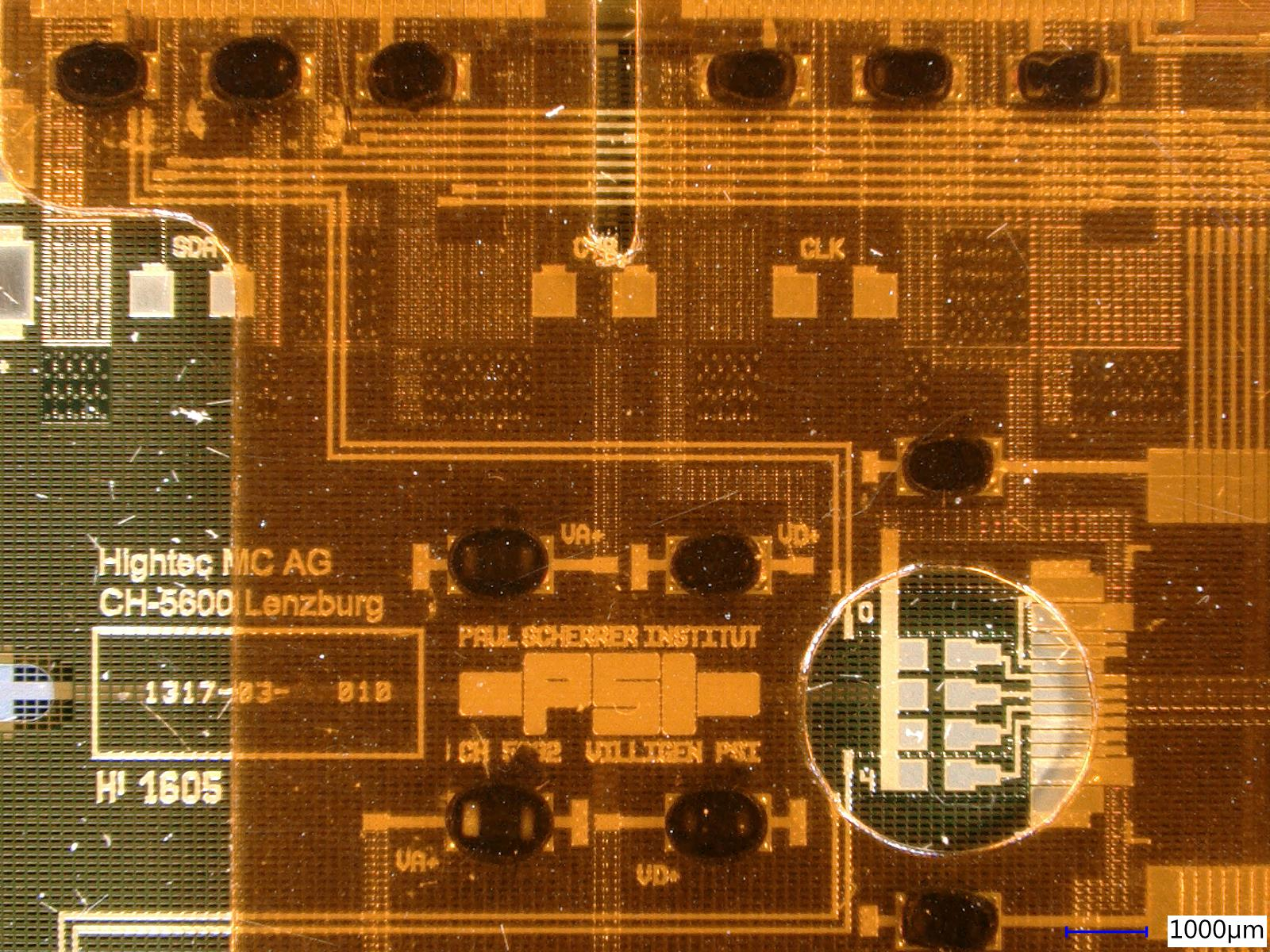

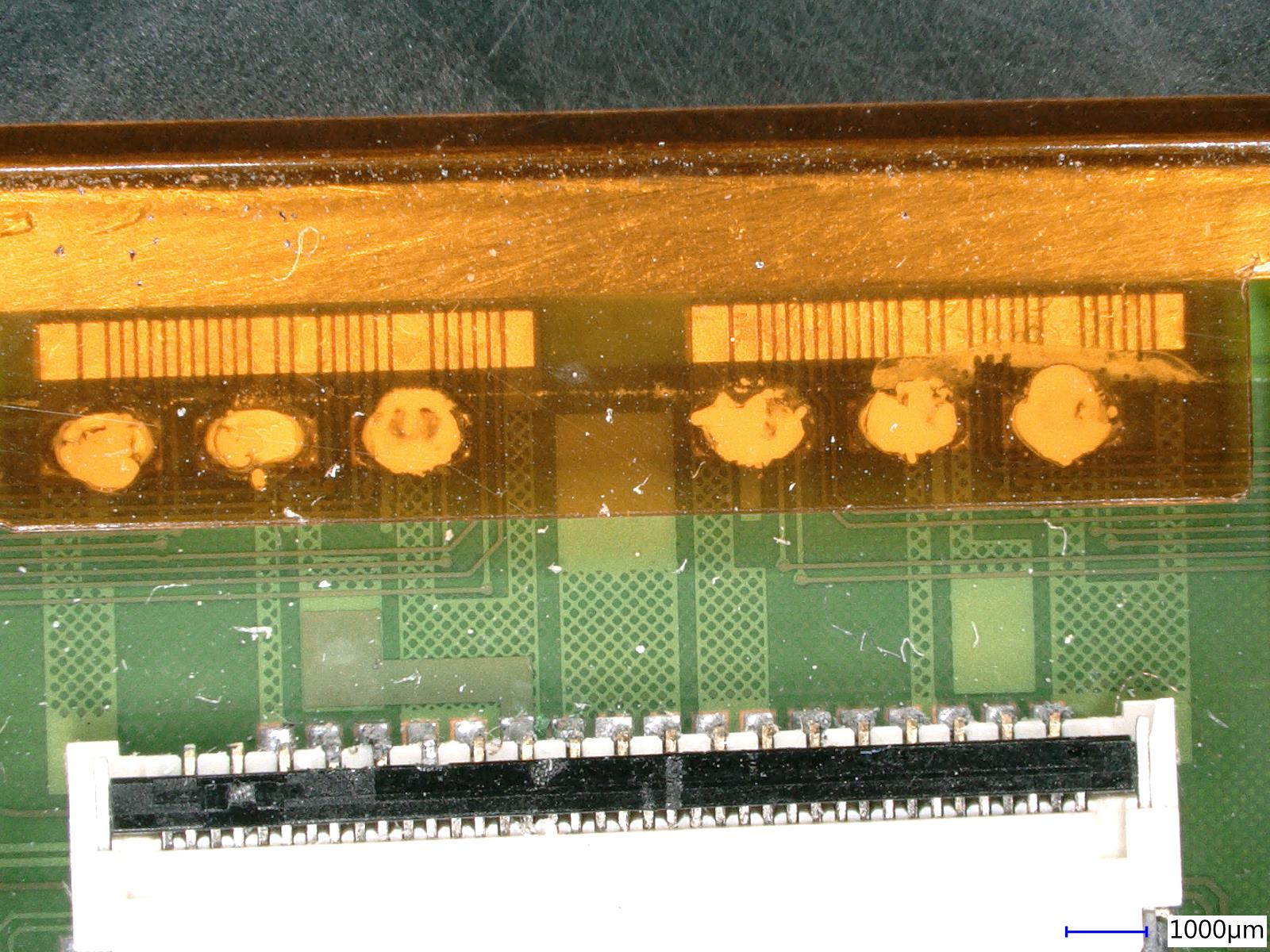

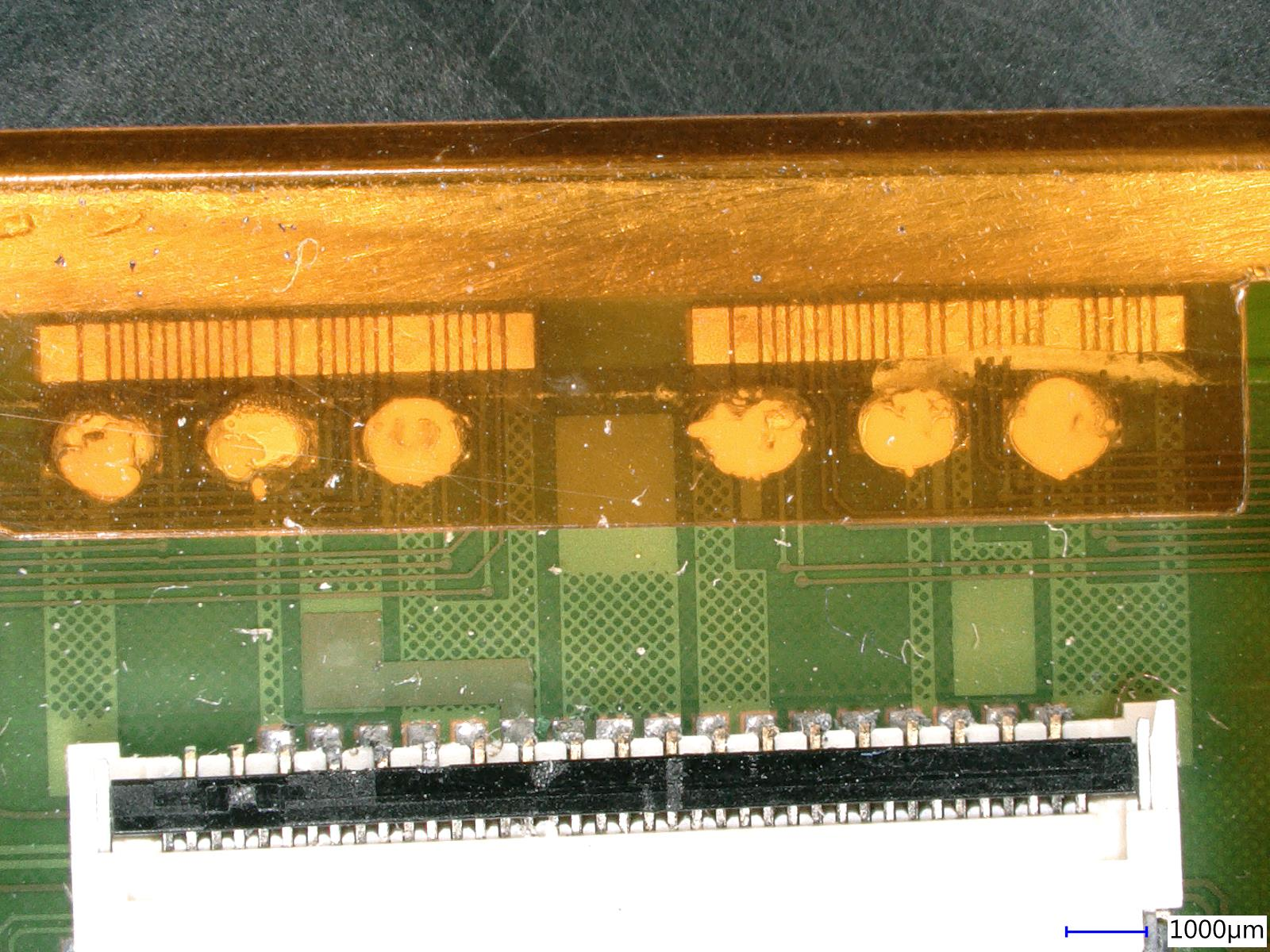

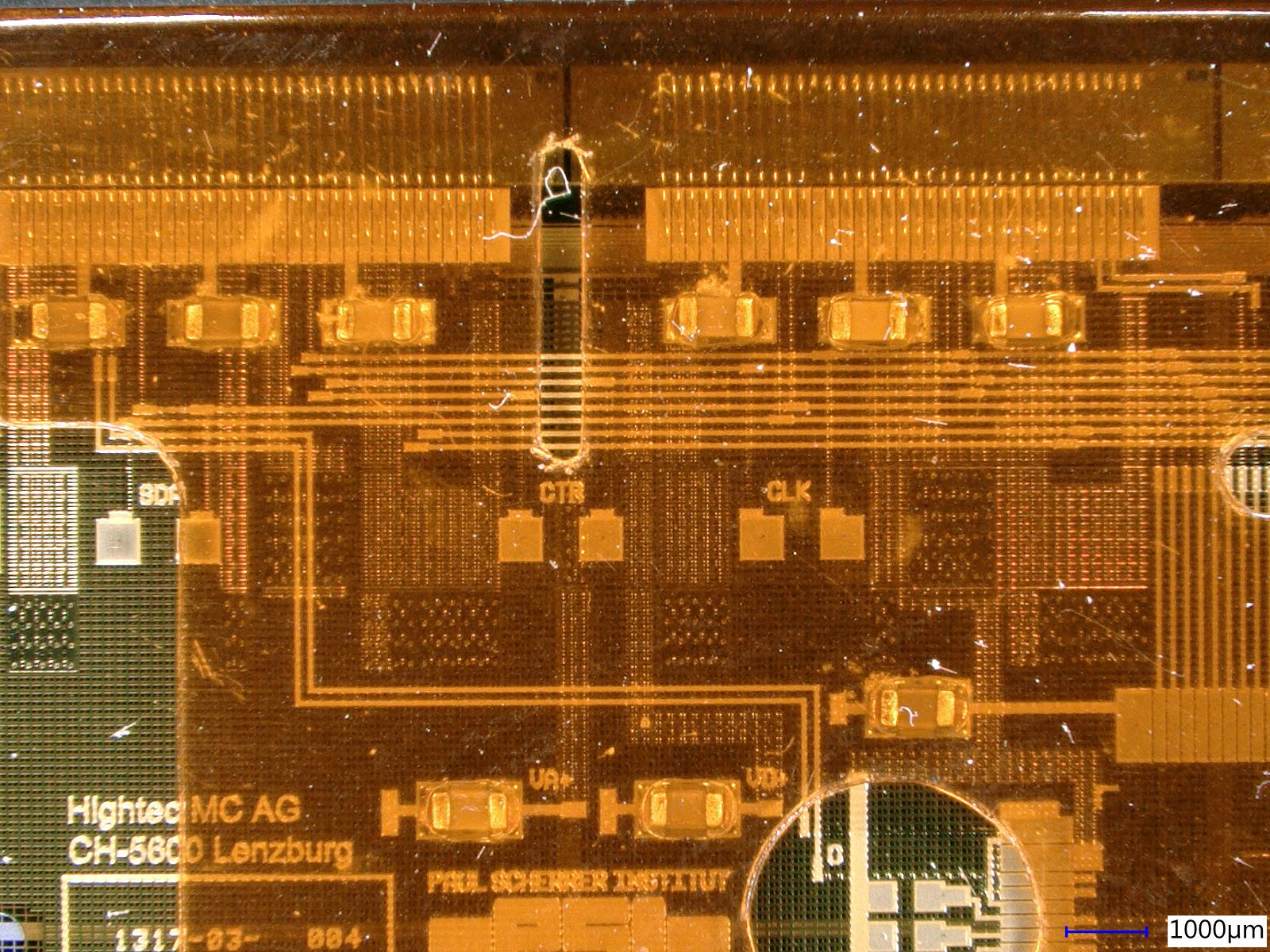

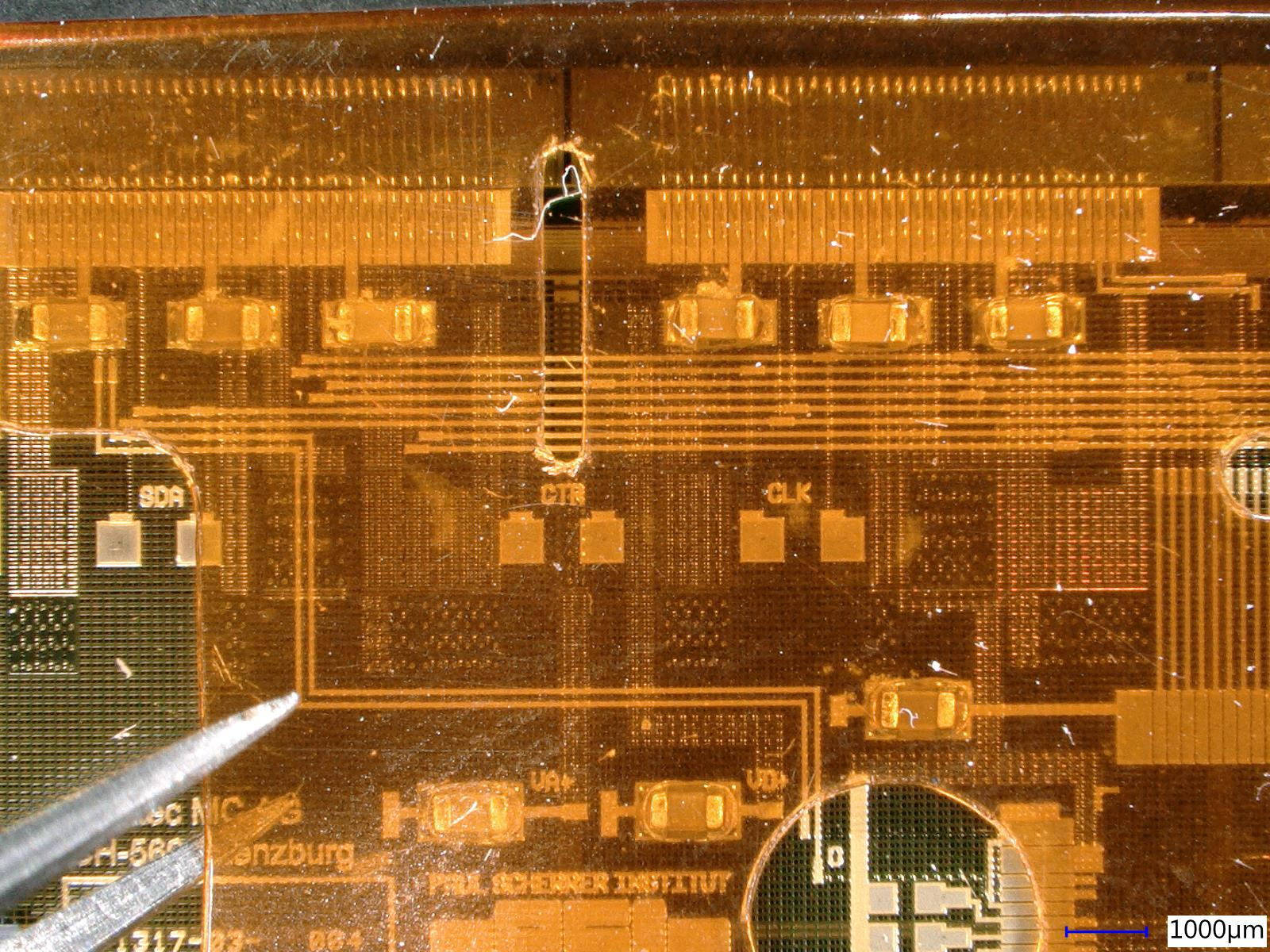

Six different glues were used to glue the cap on six dummy modules. They were all irradiated to 120 MRad in Zagreb after which they were taken to PSI and tested with the tweezers under the microscope.

Standard glue (Dow-cornig), used in CMS - it became "two-component". Solid part on the capacitors and the liquid part on the cap. Surface tension was actually holding the cap quite strongly. Silvan deemed it the second best glue

Two component epoxy adhesive - the strongest glue out of all tested. The only drawback of it was that during the application of the glue to the capacitors, it left puddles around some of them since it is quite liquid before curing. This might have been prevented if we had a proper glue stamp. The glue stamp used at the time contained too much excess glue, and if another one was printed, with small grooves where the capacitors are, the amount of glue transferred should be lower and no puddles should appear. This glue was graded the best of all the tested glues. EDIT: the glue stamp with smaller grooves was printed and now there are no puddles anymore.

SG-20 (black) - sticks, but not really well. It was also quite soft and malleable. Because it doesn't stick very well, it is not recommended for gluing the cap.

WS-200 - almost identical to the SG-20, just a different color.

Terosan MS939 - doesn't stick, not recommended.

Ergo 6521 - doesn't stick, not recommended.

Took photos of them under the microscope. There are two photos for each glue. First one is while the cap is at rest, while on the second there is an upwards force applied with the tweezers. All of them except the two component epoxy adhesive detached when force was applied. With the epoxy adehsive, the module started lifting, but the glue held. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|